Description

Package Include

Komatsu 82E-6 to 98E-6 Engine Series Workshop Manual

Language

English

Format

PDF

Total Number of pages

1-385

Publication Number

SEN04211-03

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 42 mb

With This Original Factory Workshop Manual The Technician can Find and Solve any problems encountered in the operation of your Komatsu Engine Models of :

Komatsu 82E to 98E Engine Series

Komatsu Engine 3D82AE-6 PC27MR-3 20002 and up

Komatsu Engine 3D88E-6 PC30MR-3 30001 and up / PC35MR-3 15001 and up

Komatsu Engine 4D88E-6 PC55MR-3 15001 and up / WA50-6 60001 and up

[This is true Electronic pdf copy with contains high quality images and diagrams, not scanned version]

Composition of Workshop manual

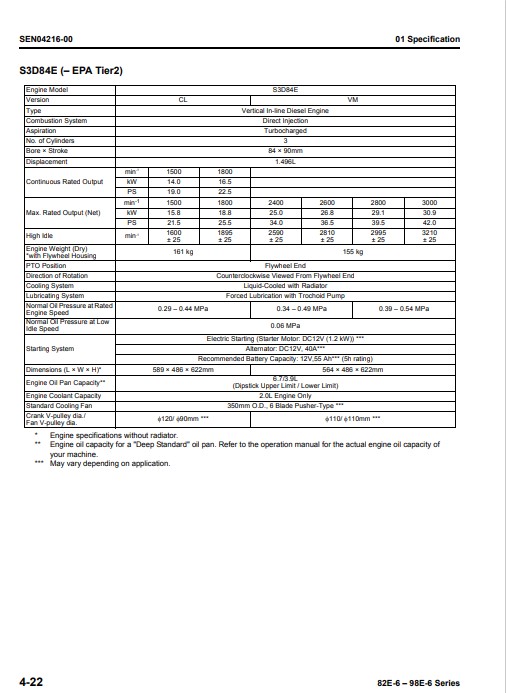

Specification and technical data

Component identification

Function of major engine components

Main electronic control components and features

Function of cooling system components

Diesel fuel

Engine oil

Engine coolant

Specifications

Principal engine specifications

Engine service standards

Tightening torques for standard bolts and nuts

Abbreviations and symbols

Unit conversions

Testing and adjusting

Testing and adjusting, Part 1

Periodic maintenance

Before you begin servicing

Introduction

Periodic maintenance schedule

Periodic maintenance procedures

Testing and adjusting, Part 2

Engine

Before you begin servicing

Introduction

Cylinder head specifications

Camshaft and timing gear train specifications

Crankshaft and piston specifications

Cylinder block specifications

Special torque chart

Special service tools

Measuring instruments

2-valve cylinder head

4-valve cylinder head

Measuring and adjusting valve clearance

Crankshaft and camshaft components

EGR system

Testing and adjusting, Part 3

Fuel system

Before you begin servicing

Introduction

Fuel system specifications

Special service tools

Measuring instruments

Fuel system diagram

Fuel system components

Fuel injection pump

Checking and adjusting fuel injection timing

Fuel injectors

Testing and adjusting, Part 4

Cooling system

Before you begin servicing

Introduction

Cooling system diagram

Engine coolant pump components

Engine coolant system check

Engine coolant pump

Testing and adjusting, Part 5

Lubrication system

Before you begin servicing

Introduction

Oil pump service information

Lubrication system diagram

Checking engine oil pressure

Trochoid oil pump

Trochoid oil pump

Trochoid oil pump

Testing and adjusting, Part 6

Turbocharger

Before you begin servicing

Introduction

Specifications

Troubleshooting

Turbocharger components

Turbocharger component functions

Washing procedure

Periodic inspection

Testing and adjusting, Part 7

Starter motor

Before you begin servicing

Introduction

Starter motor information

Starter motor specifications

Starter motor troubleshooting

Starter motor components

Starter motor

Testing and adjusting, Part 8

Alternator

Before you begin servicing

Introduction

Dynamo and alternator information

Alternator specifications

Dynamo specifications

Alternator troubleshooting

Alternator components

Alternator wiring diagram

Alternator standard output

Alternator .

Dynamo component location

Dynamo wiring diagram

Operation of dynamo

Dynamo standard output

Testing of dynamo.

Dynamo

Troubleshooting

Troubleshooting of mechanical system

Special service tools

Troubleshooting by measuring compression pressure

Quick reference table for troubleshooting

Failure Diagnostic List